牛骨粉设备 泉州肉骨粉设备 欢迎选购

价格:0.00起

产品规格:

产品数量:

包装说明:

关 键 词:泉州肉骨粉设备

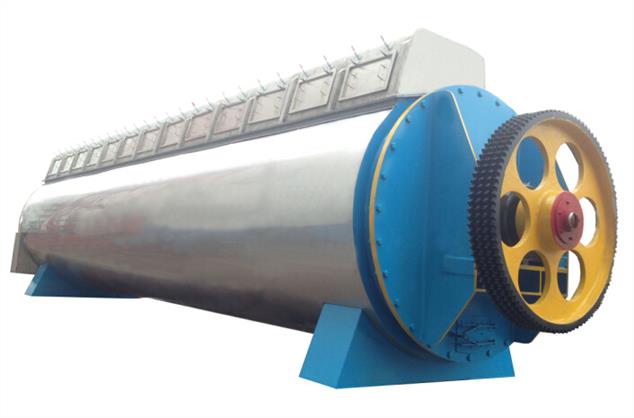

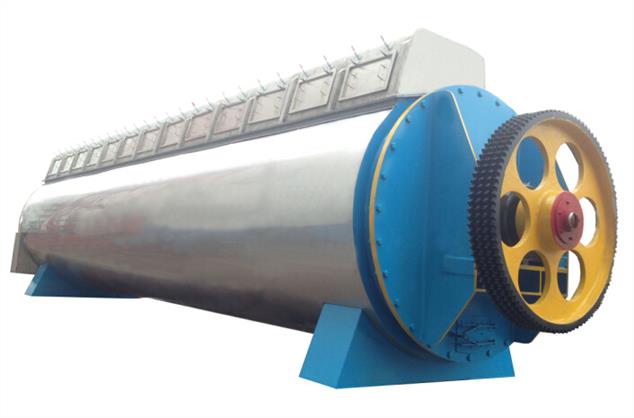

行 业:机械 干燥设备 烘干机

发布时间:2023-06-02

北海新宏恒达机械设备有限公司可以根据不同国家、不同客户的实际情况和需求,为客户量身打造的解决方案,包括项目进行规划包括场地设计、生产线设备配置、优化设备性能或进行节省成本的优化。除了对项目进行规划,公司还可负责进行全线设备的安装和试产调试,以确保整个生产线匹配客户的需要并处于工作状态。简言之,公司可为客户提供“交钥匙”工程。不管是有无从业经验的投资者,公司均可以的知识和服务迅速帮助客户在行业中取得丰硕成果。

Since 2016, BEIHAI XINHONG HENGDA MECHANICAL EQUIPMENT CO., LTD has made a breakthrough progress in the development of equipment. Due to domestic equipment and technology are relatively backward, especially in the treatment of grease technology, the original domestic equipment process could only do 23-32% of the oil content at most. After tireless efforts, BEIHAI XINHONG HENGDA's new technology and new equipment can skimmed grease to less than 12%, whose machine has become the leading brand of the industry, winning the trust of more and more customers. With the company's continuous investment in software and hardware, the BEIHAI XINHONG HENGDA brand has become one of the well-known brands in the domestic and foreign industries.

北海新宏恒达机械设备有限公司的产品遍布国内沿海各省份。同时,公司积极拓展国际市场,出口**东南亚、中东、非洲、南美洲等国家,包括越南、印度、泰国、巴基斯坦、、菲律宾、印度尼西亚,中东国家阿曼,非洲国家埃及、摩洛哥、突尼斯、毛里塔尼亚、塞内加尔、南非等,以及南美洲国家智利、秘鲁、墨西哥和苏里南等。

Beihai Xinhong Hengda Mechanical Equipment Co., Ltd now has many machines running at coastal provinces as well as other parts of the world, such as Southeast Asia, the Middle East, Africa, and South America, including Vietnam, India, Thailand, Pakistan, Myanmar, the Philippines, Indonesia, Oman, Egypt, Morocco, Tunisia, Mauritania, Senegal, South Africa, Chile, Peru, Mexico and Suriname, etc.

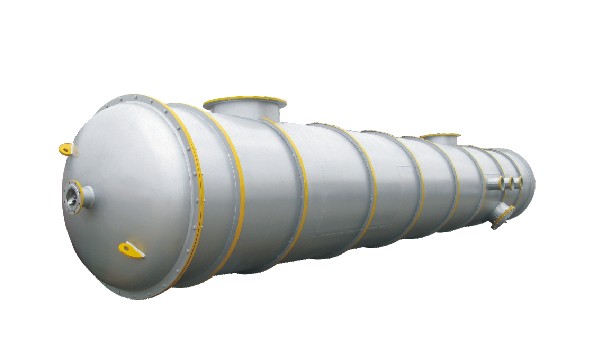

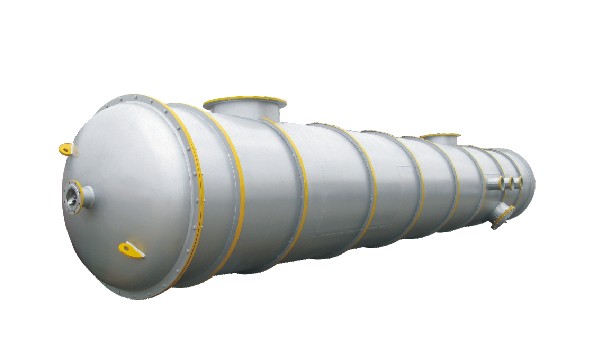

而液体经过离心机后,分离出动物油和含有部分蛋白质及其它物质的蛋白水液。鱼油存储于油罐中作为副产品外售。蛋白水液中大致有5%的固体含量,经送到浓缩设备将大量水分蒸发掉,将浓缩后成品的含固量为50%,将此蛋白水液送入干燥机乾烘干,可增加骨粉的产量和蛋白质比例。

After the liquid passes through the Tricanter, the fish oil and the protein water are isolated. Fish oil is stored in oil tanks and sold as a by-product. Protein water has roughly 5% of the solid content and then to be evaporated a large amount of water in the evaporator device. After that, the liquid has 50% of protein solid, which then will be sent to a Dryer. In this way, we can increase the fishmeal yield and protein ratio.